Vision Systems

Solve Product and Application Challenges with Automated Inspection

Delivering Comprehensive

Machine Vision Solutions

Transform your productivity with automated inspection systems. Whether you are bringing a new product to market or working to improve quality and traceability, EPIC enables you to bring your ideas to reality.

Capabilities

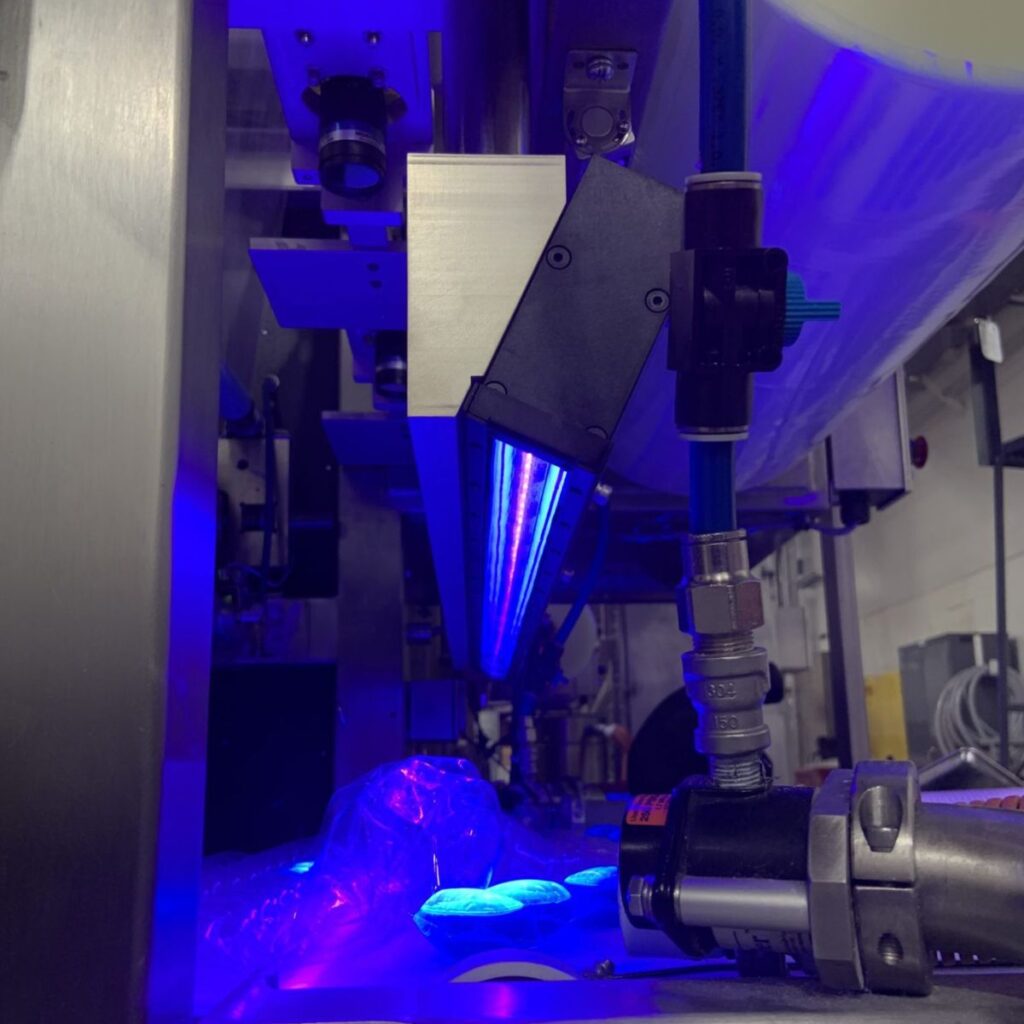

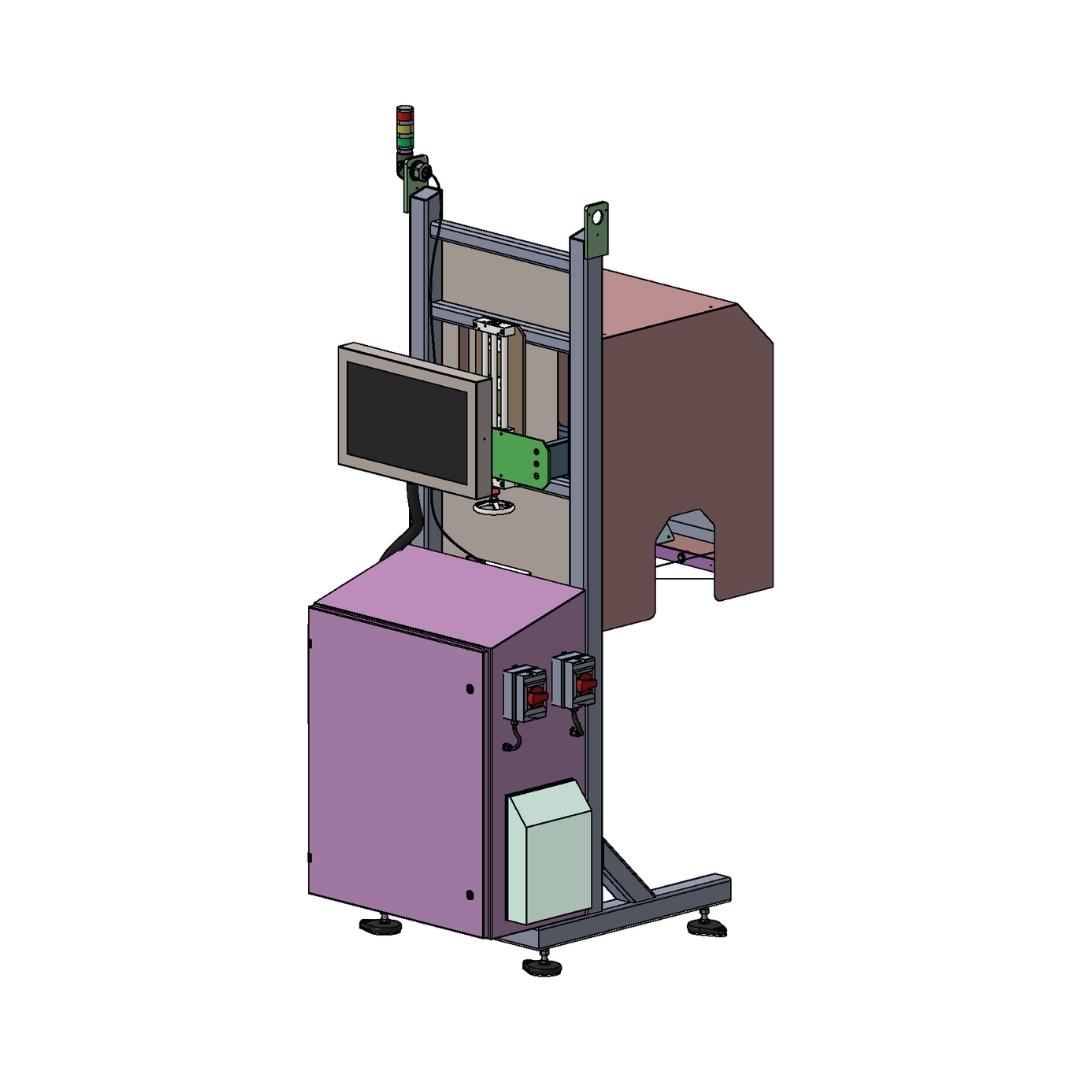

Custom-Engineered Systems

High speed, high tolerance inspection systems.

EPIC custom designs systems to meet the most complex inspection challenges.

%

Parts Inspected

%

Inspection Accuracy

Parts Per Minute

Rates are dependent on the application and other variables.

Vision System

Solutions

Damages & Defects

Improve productivity and enhance product quality:

- Holes and voids

- Damaged edges

- Artwork defects

- Bent dip tubes

- Damaged or absent closures

- Damaged or vacant spray triggers

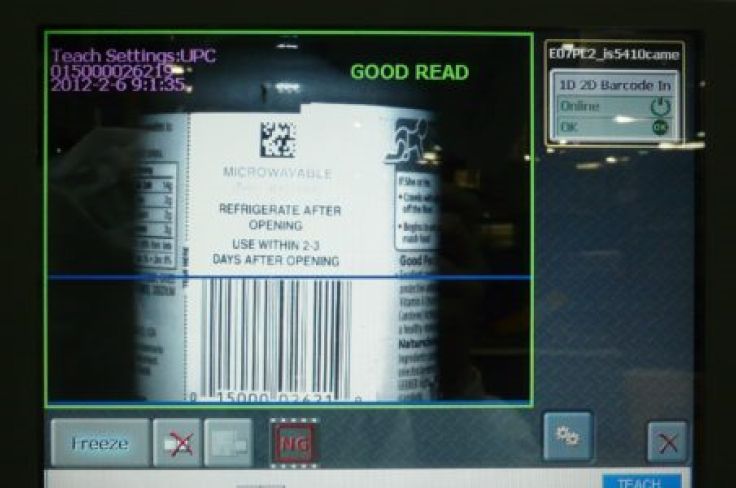

Characters & Codes

Ensure product safety while maintaining product quality:

- Dot matrix and non-dot print

- OCR and OCV

- Lot, date, and bar codes

- 1D and 2D bar codes (QR codes and custom artwork)

- Track and trace capabilities

Seal Integrity Inspections

Assure safe, reliable products and maintain consumer confidence:

- Seal contamination (product in seal inspections)

- Holes

- Channel leakers

- Cuts

Alignment & Positioning

Guarantee consistency and reliability in every finished product:

- Graphic position and alignment

- Misaligned and mislayered webbing

- Missing and misapplied labels and lids

- Part position feedback systems

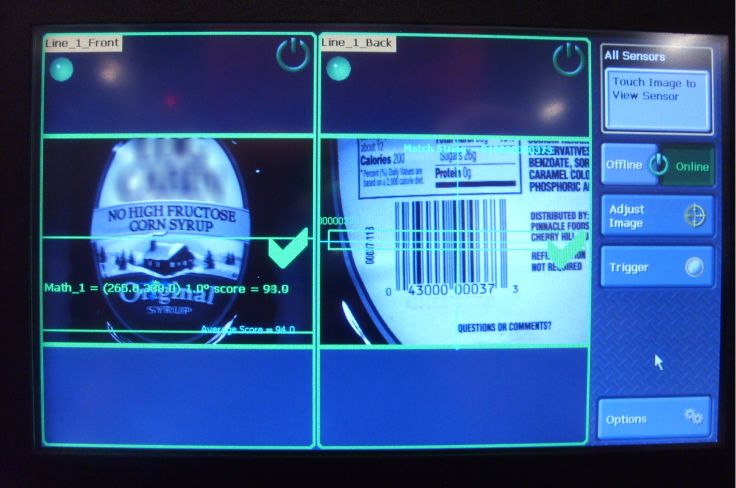

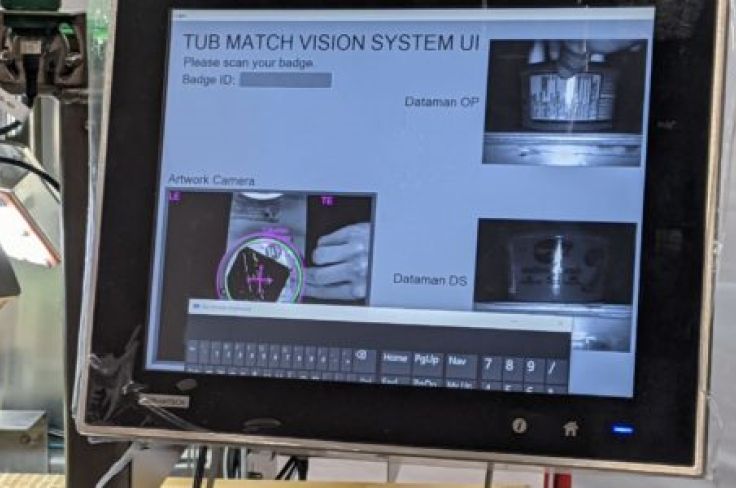

Match & Verification

Prevent recalls and returns, execute quality control at pace and scale:

- 2-piece containers

- Ensure lid and label artwork match

- Cover and container match

- Artwork and recipe verification

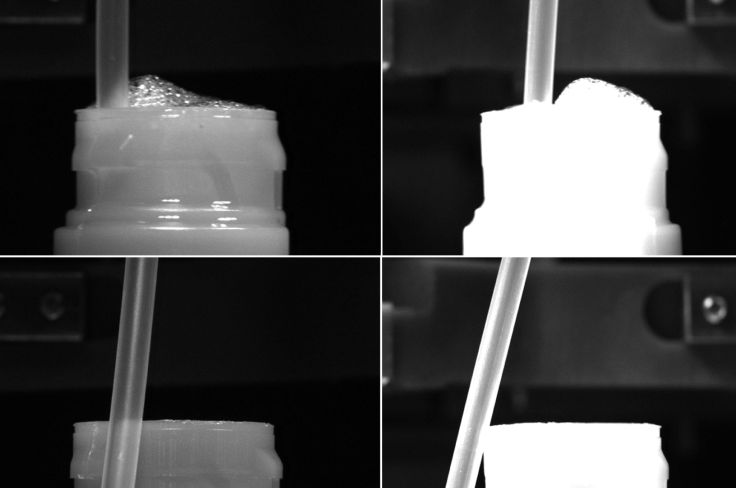

Filling & Orientation

Improve productivity and stay competitive by automating complex inspections:

- Bottle presence and orientation before filling

- Spray trigger or cap orientation

- Overfilling and leaking

- Foaming detection

- Dip tub insertion

Other Inspections

Custom solutions for discrete manufacturing inspections tailored to your product needs. Inspect for:

- 360-degree bottle inspection

- Perforation presence and depth

- Graphical inspection

Don't See What You're Looking For?

Speak to an engineer. Chances are, we have a solution for you.

Epic

Technology Partners

EPIC only selects the best equipment and instrumentation for your system. Our responsibility is to provide you with a successful solution.

Client

Success Stories

Epic Advantage

Project Methodology

At EPIC, we’re not just providers of vision systems; we’re partners in your journey towards manufacturing excellence.