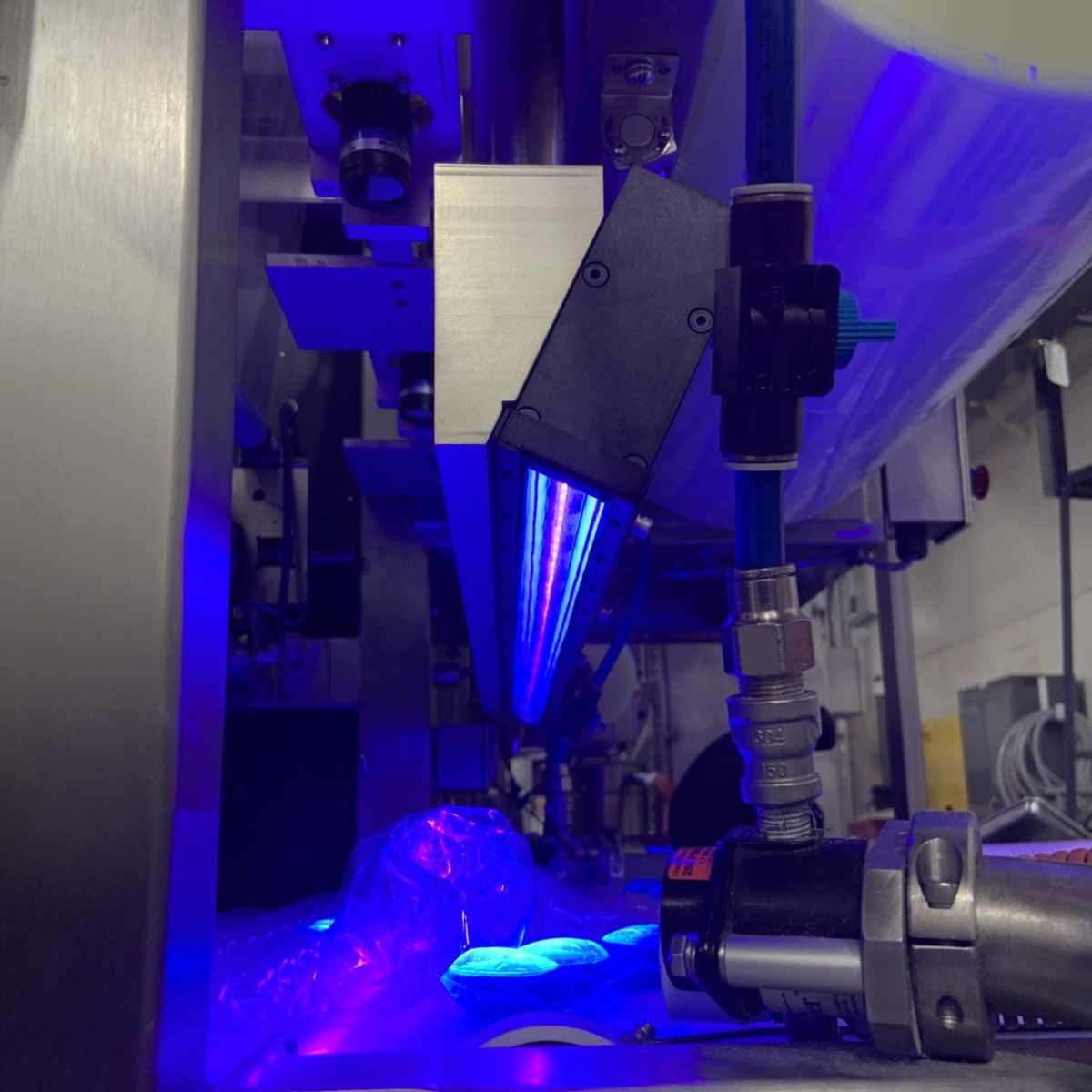

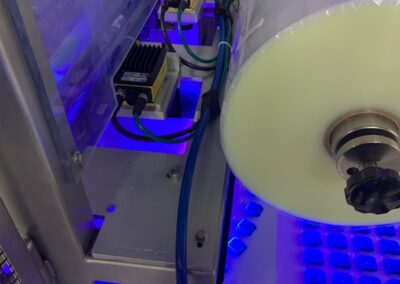

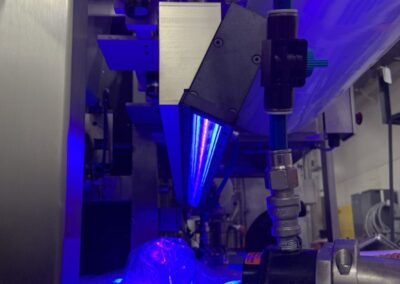

EPIC Systems automated vision inspection system addressed the customer’s challenge of detecting leaks in unit dose detergent packs. The solution provided long-term benefits ensuring efficiency, accuracy, and product quality while achieving 99.99% accuracy.

Multi-Skid Process System for a New Time-Release Fragrance Technology

EPIC’s innovative solutions and meticulous project management enabled the successful design, fabrication, and delivery of multi-skid systems, addressing many challenges faced by the consumer fragrance company and ensuring seamless production of their new product.