Vision Systems

Solve Product and Application Challenges with Automated Inspection

Delivering Comprehensive

Machine Vision Solutions

Transform your productivity with automated inspection systems. Whether you are bringing a new product to market or working to improve quality and traceability, EPIC enables you to bring your ideas to reality.

Capabilities

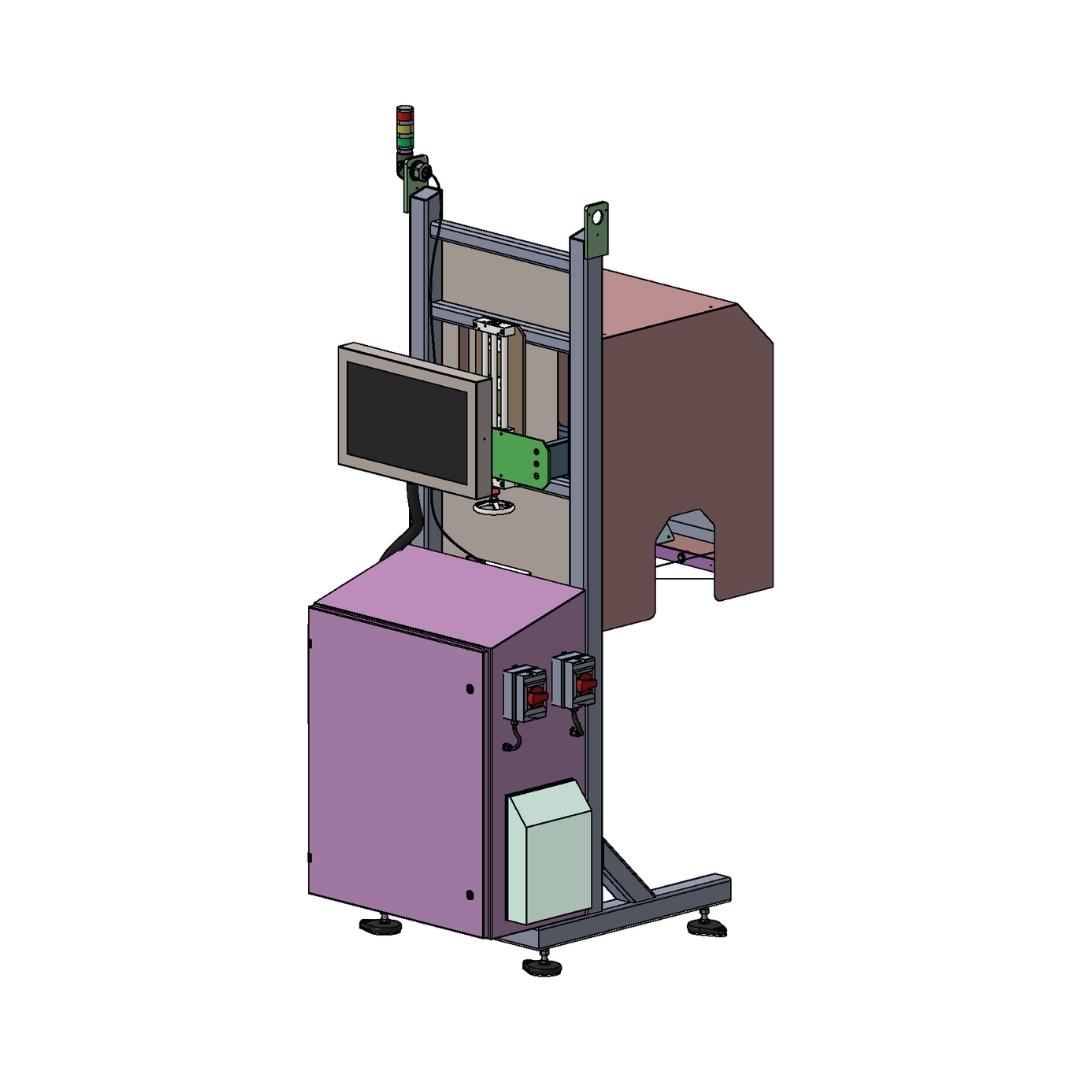

Custom-Engineered Systems

High speed, high tolerance inspection systems.

EPIC custom designs systems to meet the most complex inspection challenges.

%

Parts Inspected

%

Inspection Accuracy

Parts Per Minute

Rates are dependent on the application and other variables.

Vision System

Solutions

Damages & Defects

Improve productivity and enhance product quality:

- Holes and voids

- Damaged edges

- Artwork defects

- Bent dip tubes

- Damaged or absent closures

- Damaged or vacant spray triggers

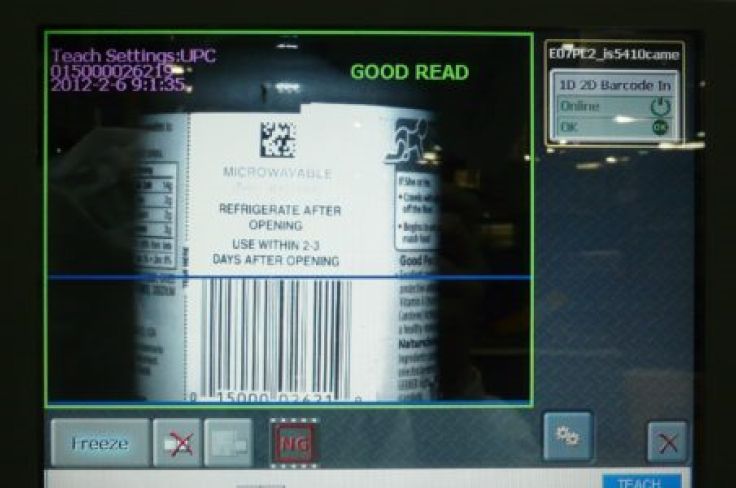

Characters & Codes

Ensure product safety while maintaining product quality:

- Dot matrix and non-dot print

- OCR and OCV

- Lot, date, and bar codes

- 1D and 2D bar codes (QR codes and custom artwork)

- Track and trace capabilities

Seal Integrity Inspections

Assure safe, reliable products and maintain consumer confidence:

- Seal contamination (product in seal inspections)

- Holes

- Channel leakers

- Cuts

Alignment & Positioning

Guarantee consistency and reliability in every finished product:

- Graphic position and alignment

- Misaligned and mislayered webbing

- Missing and misapplied labels and lids

- Part position feedback systems

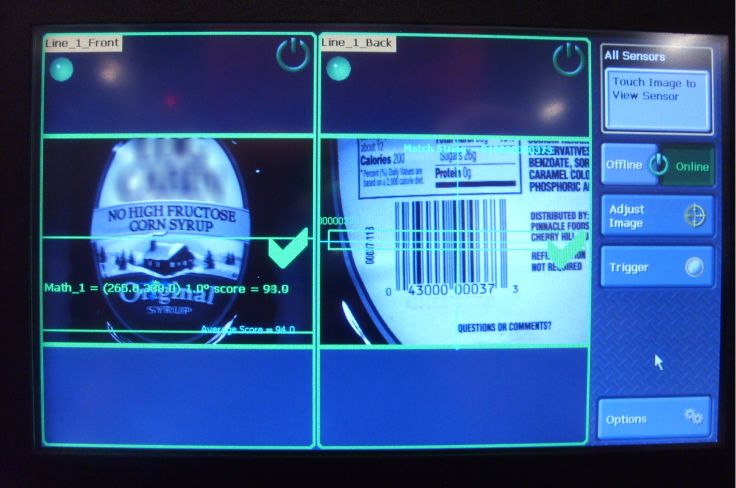

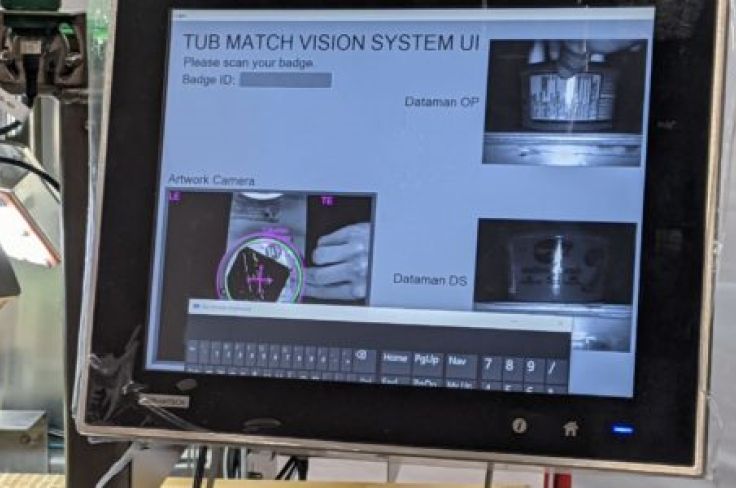

Match & Verification

Prevent recalls and returns, execute quality control at pace and scale:

- 2-piece containers

- Ensure lid and label artwork match

- Cover and container match

- Artwork and recipe verification

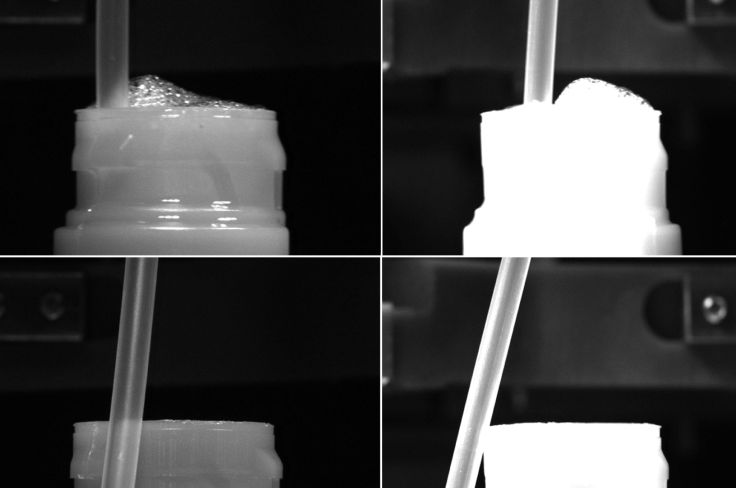

Filling & Orientation

Improve productivity and stay competitive by automating complex inspections:

- Bottle presence and orientation before filling

- Spray trigger or cap orientation

- Overfilling and leaking

- Foaming detection

- Dip tub insertion

Other Inspections

Custom solutions for discrete manufacturing inspections tailored to your product needs. Inspect for:

- 360-degree bottle inspection

- Perforation presence and depth

- Graphical inspection

Don't See What You're Looking For?

Speak to an engineer. Chances are, we have a solution for you.

Epic

Technology Partners

EPIC only selects the best equipment and instrumentation for your system. Our responsibility is to provide you with a successful solution.

Client

Success Stories

High Definition Line Scan Imaging Machine for Defect Inspection

EPIC System exceeded the customer‘s expectations, delivering a fully functional batch identification system with high-resolution imaging capabilities for QA purposes. The system provided detailed images showcasing product qualities and defects as well as streamlined the identification process, enhancing overall quality assurance protocols.

Epic Advantage

Project Methodology

At EPIC, we’re not just providers of vision systems; we’re partners in your journey towards manufacturing excellence.