As part of the Front-End Engineering (FEE) stage, EPIC joined forces with Akermin to address these challenges head on. The collaboration began with the development of piping and instrumentation diagrams (P&ID’s) based on customer’s lab-scale test data and process flow diagram (PFD). The distillation pilot plant design underwent multiple revisions during this phase, emphasizing collaboration between Akermin and EPIC.

EPIC’s innovative solution started with the utilization of stainless steel tubing instead of traditional piping. This not only ensured faster installation but also contributed to significant cost efficiency. The design team worked diligently to narrow temperature and pressure profiles, meeting critical scalability requirements within Akermin’s budget without compromising technical capabilities.

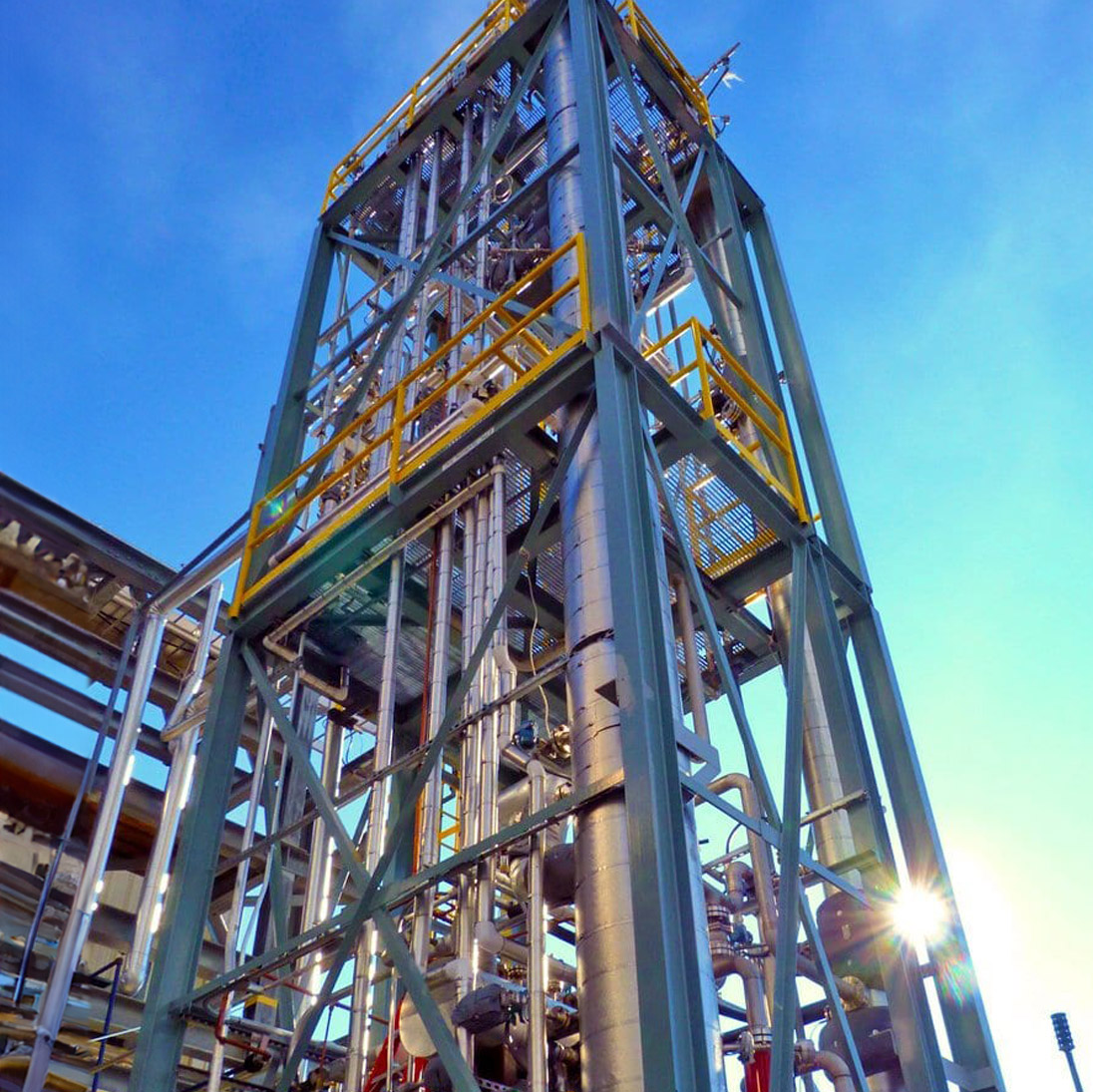

A comprehensive lifting plan was developed before fabrication moved forward, covering crane size, placement, shipping method, and skid size, ensuring a smooth installation process. The plan meticulously examined the path to the final destination at the utility plant, ensuring the skid dimensions fit through constrained spaces.

Instrumentation placement became a focal point of the solution, strategically positioning probes, nozzles, and valves between layers of packing and distribution plates. Correct orientation ensured easy access for operators and maintenance personnel, preventing interference and ensuring the functionality of the test module.

The innovative modular skid design allowed for safe and timely construction outside the hazardous power plant environment. This not only enhanced efficiency but also proved to be a cost-effective and safe alternative. Scheduling work around power plant operations, a potential challenge, was overcome seamlessly with the modular skid approach. The result was the successful and on-schedule delivery of a fully operational pilot skid with minimal downtime for existing operations.