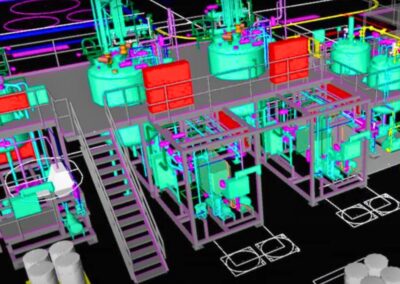

EPIC Systems rose to the challenge, scaling up the time-release fragrance technology and fabricating two multi-skid batch blending systems. One of these systems included a Clean-in-Place (CIP) module, integrated at a separate location within the client’s facility.

EPIC’s approach involved designing each skid with modularity in mind, allowing for efficient breakdown, shipping, and reassembly at the destination. Specific single-flow, self-priming Bornemann Pumps were integrated onto the batch skids to meet sanitary and sterilization requirements, ensuring formula integrity.

The systems were meticulously designed to fit within ISO containers, enabling smooth international shipping to European and Southeast Asian plant locations. Skids were disassembled, shipped securely under ISO container restraints, and successfully reassembled and installed on-site, ensuring minimal downtime.

The collaboration between the fragrance company and EPIC yielded impressive results. Both multi-skid systems were delivered to different plants on schedule and under budget, despite the tight timeframe. EPIC’s team commissioned the systems, allowing the client to begin manufacturing the newly developed product on schedule, expanding their product capabilities to end-users.