To address these challenges, EPIC Systems developed a custom-built rotatory inspection machine and integrated it into their packaging line before the filler. The machine utilized advanced machine vision technology to achieve higher detection rates, faster inspection speeds, and minimized downtime.

Cans entered the inspection machine through an in-feed screw, which positioned them accurately into a star-wheel. An overhead color camera inspected for varnish presence on the canister lip and checked for any unwanted debris inside the canister.

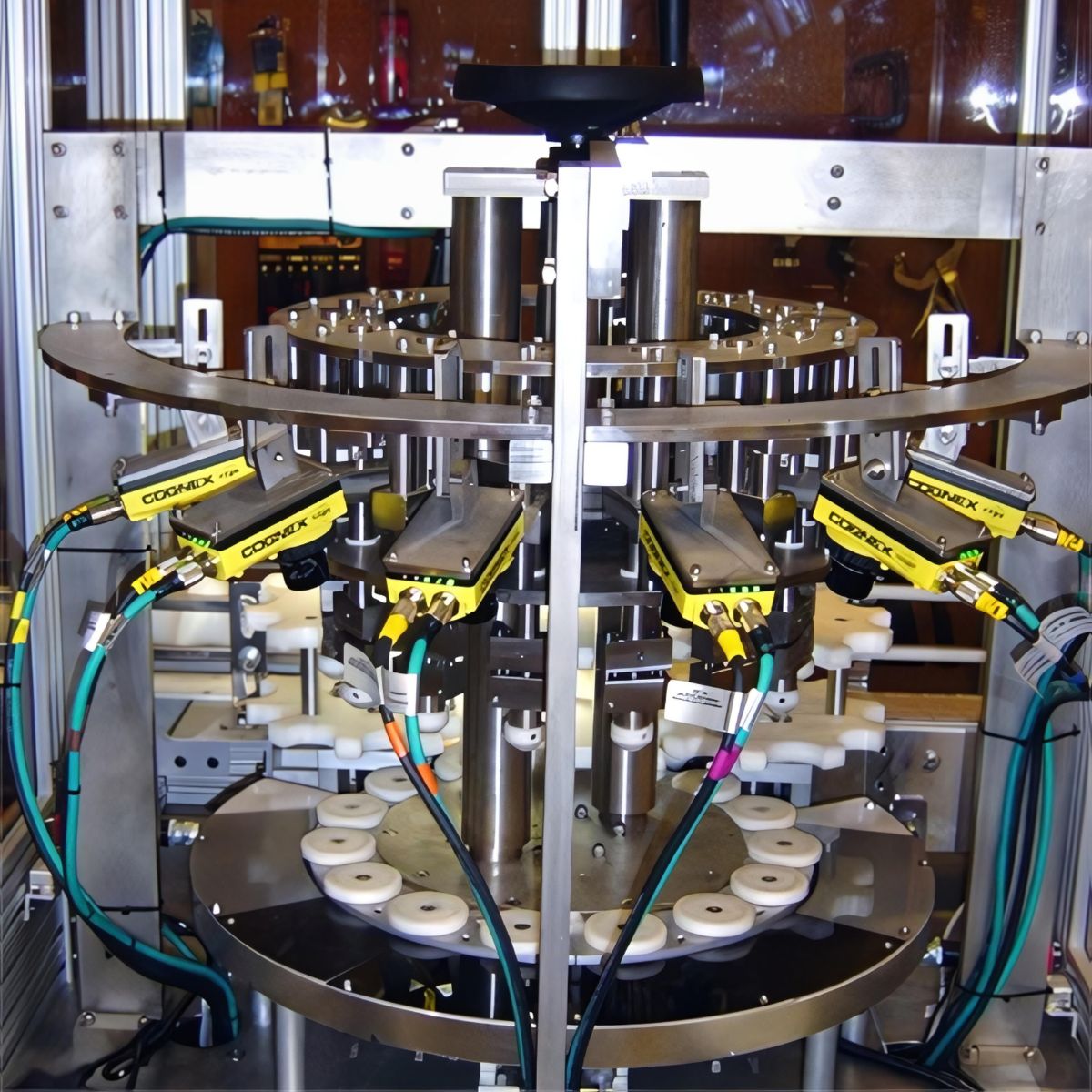

Once in the machine, cans were transferred to a platen and rotated 360 degrees within a 180-degree turn. Six overhead cameras were strategically positioned to capture a full 360-degree view of each can. These cameras scrutinized the cans for surface defects such as dents that could impede the rising of a puck inside the can after filling.

Custom lighting arrangements were employed to ensure optimal inspection conditions, minimizing interference from artwork on the can surface. Collimated lenses were utilized to enhance defect visibility, making dents appear as dark shadows against the can surface.

Defining the type of dent that could impede the puck’s movement was a complex task. However, through meticulous integration and testing, the inspection machine achieved a successful identification rate, exceeding customer specifications. Additionally, an eighth camera was later added to inspect for crushed or misshapen can lips.

In the event of a failed inspection, triggered by missing varnish, debris, crushed lips, or dents, a shift register mechanism was activated. This mechanism mechanically moved the failed cans through the inspection machine while allowing compliant cans to proceed onto the conveyor.