To address the safety concerns, EPIC Systems took a comprehensive approach starting with a Process Hazard Analysis (PHA). This involved an in-depth examination of every aspect of the manufacturing facility to identify potential hazards and failure points at the manufacturing facility and assigning a risk level to each identified issue. Collaborating closely with the client to understand their risk tolerance and utilizing Layers of Protection Analysis (LOPA), EPIC devised a safety control system that aligned with the specified safety requirements.

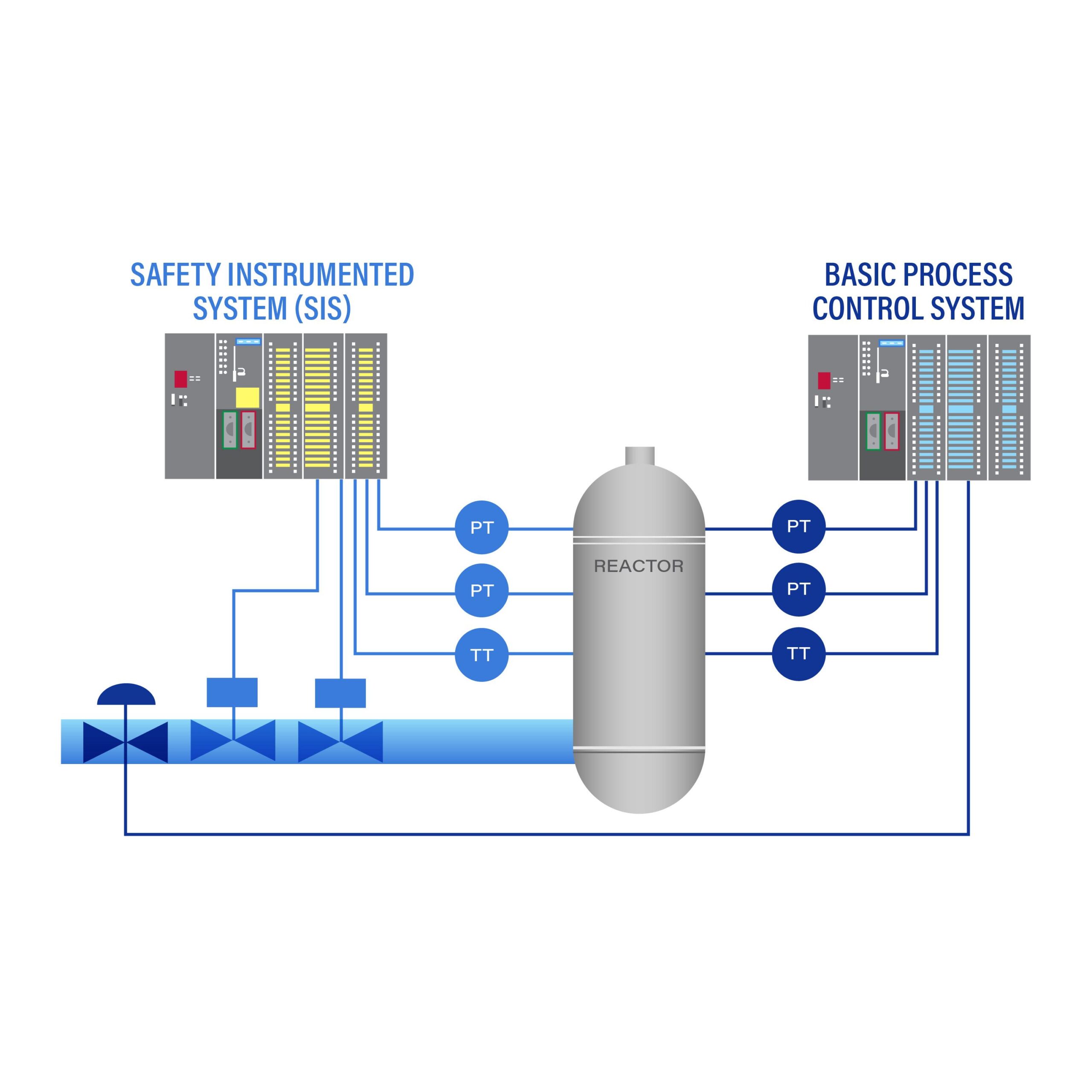

The solution included a fully customized SIS (Safety Instrumented System) that comprised of nearly 30 SIFs (Safety Instrumented Functions), ranging from SIL1 to SIL3 (Safety Integrity Level) to meet the safety specifications and mitigate identified risks. To maintain operational continuity, the design encompassed a control system that seamlessly operated in conjunction with existing equipment.

EPIC also integrated mechanical components, introducing additional safety devices to enhance the overall safety infrastructure. All components were rigorously wired back to the control system with the correct ratings to ensure system integrity.

EPIC engineers wrote and implemented code to continuously monitor and observe the SIS (Safety Instrumented System) and established a real-time monitoring system to detect anomalies promptly and enable swift corrective actions. Comprehensive testing protocols were developed and implemented to guarantee the on-going effectiveness of the newly integrated safety measures.

EPIC’s responsibilities covered a wide scope, including:

- Safety Requirements Specification (SRS)

- Proof Test Procedures

- Updated Piping and Instrumentation Diagrams (P&IDs)

- Equipment and Instrument Lists

- Instrument Data Sheets

- Mechanical and Electrical Bid Packages

- Installation Instructions

- Electrical Design, Control Panels

- Safety PLC and HMI programming

- On-site Commissioning

- Turnover Document Package