EPIC Systems approached these challenges with a comprehensive strategy tailored to the client’s requirements. During a Front-End Engineering (FEE) stage, EPIC engineers developed a physical modular plant and Piping and Instrumentation Diagrams (P&IDs) based on client-provided lab-scale testing data and process flow diagrams. Detailed discussions with the client refined the concept and operational stages, with additional recommendations for intermediate processing steps.

Final P&IDs were meticulously developed, and scale-up work began using 2D and 3D modeling software, ensuring a thorough understanding of the plant’s layout and design.

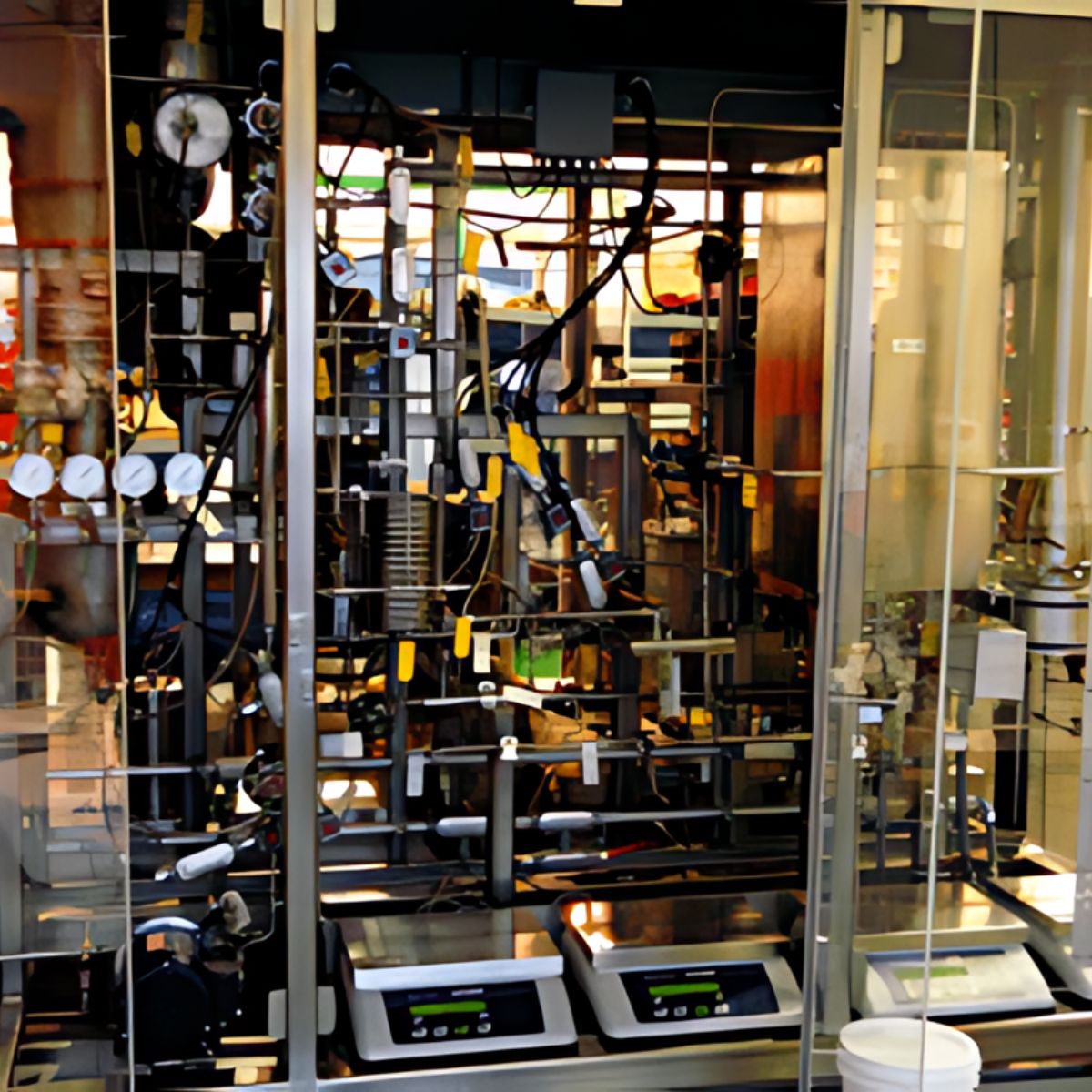

EPIC delivered a self-contained automated advanced laboratory skid capable of multi-stage biomass to liquid fuel conversion, incorporating industrial technologies suitable for production-scale operations. This included designing a demonstration skid with a specialized industrial heater to test the production-sized heating process.

Since there were no pre-existing utility systems for this plant, EPIC’s scale-up specialists included an exhaust system, drainage system, and spill management system within the pilot plant itself. This eliminated the need for external site modifications. Additionally, the fully enclosed design of the skid ensured containment within the unit, enhancing safety protocols.

Strategic placement of over a dozen sampling points allowed the client to monitor process efficiencies and product states, while a valving system facilitated the collection of multiple samples at different operational stages for analysis.

An extended testing period at EPIC’s fabrication shop enabled the identification and resolution of unforeseen issues, saving the client significant time during the on-location start-up phase.

Once finalized, the pilot plant was certified as safe for lab workers. Its modular design facilitated easy relocation to other facilities or repurposing for different projects. Guided by EPIC’s scale-up specialists, the final skid offered a precise roadmap for the full-size buildout of the pilot plant.