If you’re reading this blog, chances are you may be familiar with the benefits of machine vision systems to the manufacturing and packaging industries. When properly designed, automated vision inspection systems allow for higher speeds of inspection, with greater accuracy. The important phrase to note here is “properly designed.”

The alternative? Find a vision integrator that is capable of collaborating as your partner. In an ideal partnership, you would take your own knowledge of industry-specific challenges and combine them with the vision integrator’s knowledge of vision systems design, fabrication, programming and integration. Such a partnership will provide your company with increased inspection quality, customization and repeatability. Let’s take a deeper look at each of these.

Increased Customization

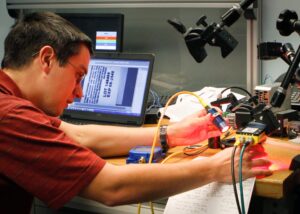

Working with a vision integrator partner means that they can take the time to fully understand your process, and by doing so, provide a system that is custom-designed for your specific inspection parameters. Whether you need to inspect at a high rate of production or within a limited amount of space, being able to rely on a vision integrator that can design a vision system around these challenges will alleviate any concern of purchasing a big, expensive paperweight. A vision systems integrator will take your project from application design to R&D, and finally to programming and installation.

Increased Repeatability

Another benefit of having a custom-designed vision system for your process is the ability to leverage initial engineering and design to fabricate multiple replica systems at a reduced cost. Whether your production lines are in the same plant or in different plants across the world, having documented and detailed vision system designs will ensure repeatability and accuracy across every line. Having established this fruitful partnership, your vision integrator should also be able to make necessary changes to fit inspection systems into plants that have variances in their design and layout.

Increased Quality

Quality, in terms of vision systems, is measured in two ways – the quality of the system itself and the quality of the inspection it provides. Working with a machine vision integrator will provide both. Choosing a good partner means choosing someone who can provide systems for high-speed, high production rate lines that have stringent pass/fail rates and a high degree of precision for measurement or gauging. Besides providing a quality inspection, partnering with a good machine vision integrator will provide you with vision systems that withstand the test of time. This means you can forget about the costs associated with maintenance and re-calibration of those out-of-the-box systems.

If you are looking for a high-quality machine vision system that is designed for your specific inspection parameters, contact EPIC Systems. EPIC Systems has provided custom engineered machine vision systems to Fortune 500 and top private companies with continued success and satisfaction. To learn more contact us today or call 314-806-1678.