In the ever-evolving landscape of industrial processes, companies are constantly seeking innovative solutions to enhance efficiency, reduce costs, and minimize project timelines. One such solution gaining significant traction is the offsite fabrication of modular process skids. This method offers a range of benefits that revolutionize the traditional approach to construction and installation in various industries.

Fast Construction, Lower Costs

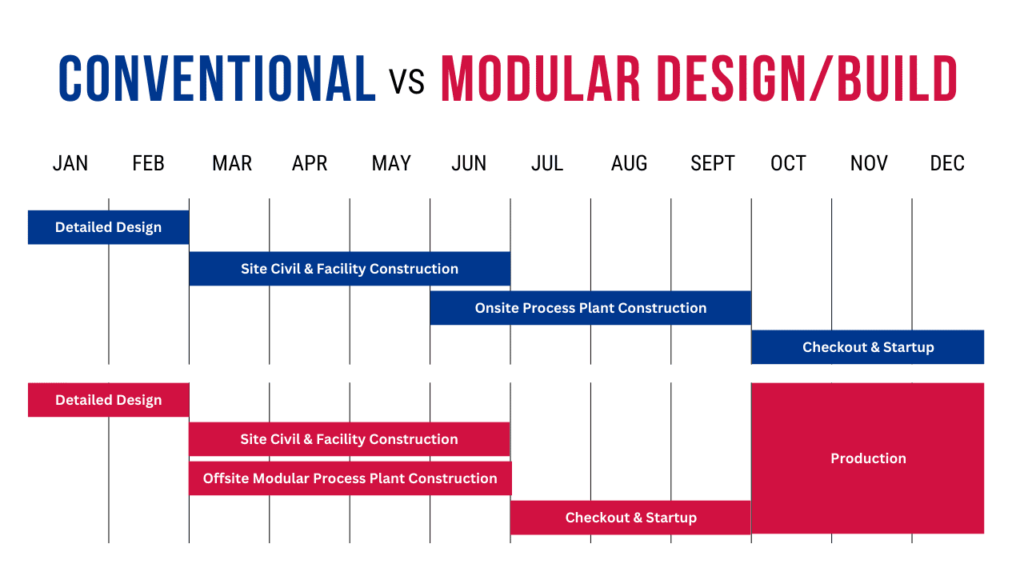

A pivotal advantage of offsite fabrication lies in the accelerated speed of modular design and build. Unlike traditional stick-built systems, modular process skids can be constructed concurrently with onsite groundwork. This parallel construction process translates to shorter project timelines, leading to getting your system operational in the plant much quicker. Going this route can reduce the project timeline by as much as four (4) months!

Additionally, smaller onsite crews are needed for modular skid systems installation, mitigating labor expenses.

Uninterrupted Operations

Perhaps one of the most critical advantages of offsite fabrication is its minimal impact on existing operations. Traditional construction methods often necessitate plant shutdowns or interruptions, leading to downtime and potential revenue loss. With modular process skids, offsite construction ensures that pre-existing operations continue without disruption.

Capital Efficiency through Repeatability

For projects involving multiple units, offsite fabrication allows for maximum capital efficiency. By designing a modular process skid once and replicating it, companies can achieve considerable savings in both design and construction costs. This standardized approach ensures consistency and quality across all units, streamlining the entire construction process.

Reduced Material Usage

With modular design and construction, materials are optimized for each skid, resulting in reduced waste, a stark contrast to traditional stick-built systems. This reduction is not only contributing to cost savings but also aligns with sustainable practices, promoting environmental responsibility in industrial operations.

Improved Safety Measures

The offsite fabrication of modular process skids introduces a range of safety benefits. By reducing onsite construction time, there are fewer OSHA exposure hours for plant personnel. Additionally, the need for smaller onsite crews contributes to a safer working environment. Construction that occurs in the controlled conditions of a fabrication facility further minimizes safety risks associated with adverse weather or challenging onsite conditions.

Consistent Workforce Expertise

Offsite fabrication often involves highly trained and experienced assembly and fabrication technicians employed by the modular system provider. This guarantees a consistent level of workmanship and availability of skilled workers throughout the construction process.

The offsite fabrication of modular process skids is a game-changer for industries seeking efficiency, cost-effectiveness, and enhanced safety measures. By embracing this innovative approach, companies can not only streamline their construction processes but also pave the way for a more sustainable and resilient future in industrial operations.