How Industrial Steam Stripping Works:

Steam distillation, or steam stripping, is a continuous distillation technique to separate organic compounds from water. VOC’s can be removed from air, gas or liquids using steam stripping, which takes advantage of lower boiling points or limited solubility of the compounds in water.

Steps for industrial steam stripping:

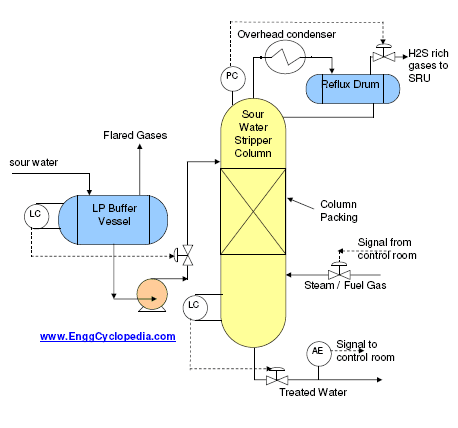

- The VOC contaminated process is fed to the top of the stripping column.

- Live (or reboiled) steam is fed to the bottom of the stripping column.

- As the steam rises it evaporates volatile organics and a portion of it becomes condensed.

- The overhead vapor leaving the top of the stripping column is condensed.

- The condensed Overheads are often decanted to separate into an organic product and a water layer saturated with organics.

- If VOCs are soluble in water, rectification stages and refluxing may be added to the column to further remove water from the process.

- The water layer can be recycled to the feed vessel or is sometimes refluxed back to the column to increase the efficiency and/or degree of separation.

- The bottoms stream from the stripping column, with VOCs removed to design specifications can be recycled as process water or discharged.

Looking for more information on distillation systems? Here are a few resources you may want to check out:

- Steam distillation systems from EPIC

- Industrial distillation systems

- Basics of distillation column design

- A step-wise procedure to advanced distillation column design

- Distillation projects gallery