In the realm of pet care, one of the paramount concerns for pet owners is the quality and safety of the food they provide to their furry companions. Understanding the significance of this issue, regulatory bodies like the Association of American Feed Control Officials (AAFCO) continuously update guidelines to ensure the transparency and reliability of pet food labels. At its 2023 Annual Meeting, AAFCO took a significant step forward by approving new guidelines for dog and cat food labels, termed Pet Food Label Modernization (PFLM). This move aims to enhance consistency and transparency, empowering consumers to make informed choices about the food they offer their pets.

The implementation of PFLM represents a proactive approach to addressing evolving consumer needs and advancements in the pet food industry. Major changes include a new Pet Nutritional Facts Box, resembling human food labels, and a new standard for the intended use statement, aiming for consistency across product categories and enhancing consumers’ understanding of product usage. However, compliance with these regulations requires solutions that streamline processes and ensure adherence to standards.

One such solution is the integration of Machine Vision inspection systems into the manufacturing and packaging processes of pet food manufacturers. These advanced systems offer a multifaceted approach to compliance, addressing various aspects of label verification and product quality control.

Optical Character Recognition (OCR)

Machine vision inspection systems play a crucial role in ensuring label legibility, a key requirement outlined in the PFLM guidelines. By employing optical character recognition (OCR) technology, these systems can accurately decipher text on labels, ensuring that vital information such as ingredient list and nutritional content is clearly visible to consumers. It enables quick detection of errors, such as misspellings or inconsistencies, minimizing the risk of product recalls and regulatory non-compliance.

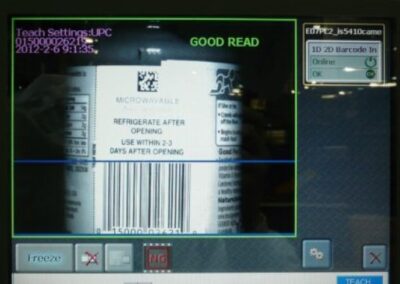

Label Inspection

Through high-resolution imaging and sophisticated algorithms, machine vision systems can detect defects or inconsistencies in labels, ensuring compliance with regulatory standards. Whether it’s improper labeling of ingredients or inaccurate nutritional claims, these systems provide manufacturers with the tools to rectify issues before products reach the market.

Track and Trace

Machine vision inspection systems facilitate track and trace capabilities, enabling manufacturers to monitor the entire production process from raw ingredients to finished products. By assigning unique identifiers, such as barcodes or RFID tags, to each item, manufacturers can track its journey from the source to the final destination. This enables real-time visibility into the production flow, allowing for proactive identification of any deviations or issues that may arise. Additionally, track and trace systems facilitate recall management by quickly identifying affected products and minimizing the impact on consumers and the brand’s reputation.

Inspection Data and Insights

The implementation of automated machine vision inspection systems yields valuable data and insights that can inform continuous improvement efforts. By analyzing data generated during the inspection process, manufacturers can identify trends, optimize production workflows, and enhance overall quality control measures. This proactive approach not only ensures compliance with current regulations but also fosters innovation and adaptability in response to emerging consumer preferences.

The approval of new pet food label guidelines by AAFCO signifies a concerted effort to prioritize consumer safety and transparency in the pet food industry. By leveraging innovative solutions such as machine vision inspection systems, manufacturers can navigate regulatory requirements with confidence while upholding the highest standards of quality and integrity. As pet owners continue to prioritize the well-being of their furry companions, ensuring the safety and reliability of pet food remains paramount, and advancements in technology play a pivotal role in achieving this goal.