The nationwide worker shortage continues to affect various industries, including manufacturing, and is expected to persist well into 2024 and beyond. One of the biggest contributors for this issue is the mass retirement of Baby Boomers. According to Forbes, 4 million Baby Boomers are leaving the workforce every year. Some experts call it “silver tsunami”, and its effects are now being felt throughout many industries. For manufacturers who are grappling with this demographic shift, the integration of automation and robotics becomes a viable and innovative solution.

The Current Labor Landscape

According to the Worcester Business Journal, the worker shortage crisis is unlikely to recede in 2024. The departure of skilled Baby Boomer workers from the job market has left a void that younger generations are finding difficult to fill. Despite ongoing efforts to attract new talent, manufacturers face an uphill battle in finding qualified workers to meet their operational needs. The search for solutions has become more urgent than ever, with the traditional workforce proving insufficient.

The Role of Robotics in Addressing Labor Shortages

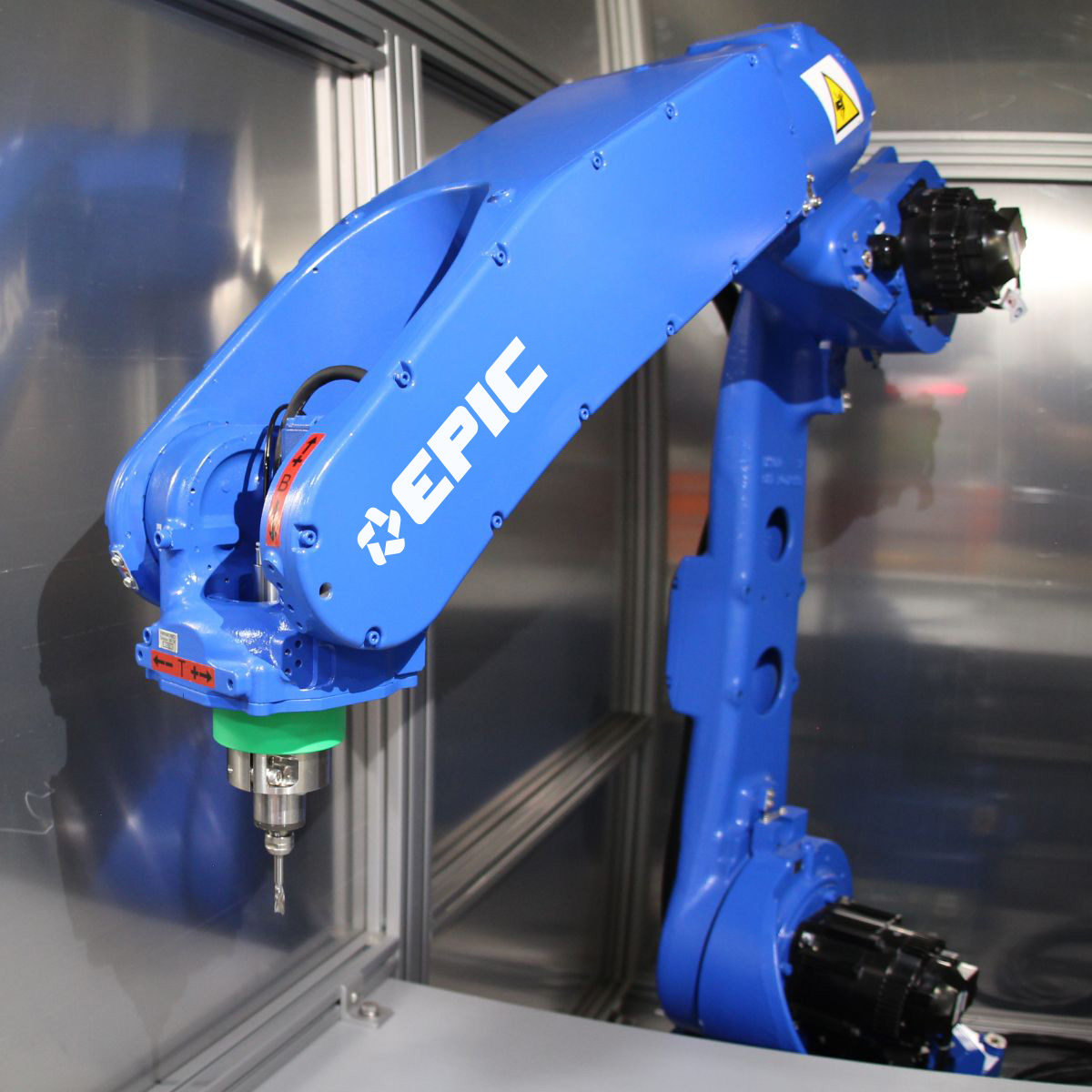

As the labor shortage crisis looms, manufacturers are turning to automation and robotics as a transformative solution. The integration of robotic technologies can help alleviate the burden on human workers and streamline manufacturing processes. Here’s how automation can play a crucial role in mitigating the challenges posed by labor shortages:

Increased Productivity and Efficiency:

Robotic systems are best suited to perform tasks that require precision and speed, significantly enhancing overall productivity. By automating mundane and repetitive processes, manufacturers can optimize their operational efficiency, leading to increased output even with a reduced human workforce. Additionally, with the introduction of cobots, or collaborative robots, where they work safely alongside or together with people, workers are able to focus on more creative, solution-oriented tasks, whereas cobots perform monotonous chores.

Precision and Quality:

Robotics excel in tasks that demand high precision and accuracy. By incorporating robots into manufacturing processes, companies can ensure consistent quality in their products, reducing errors and waste. This not only enhances the overall quality of goods but also boosts customer satisfaction.

Safety in the Workplace:

Dangerous and physically demanding tasks in manufacturing can be assigned to robots, reducing the risk of workplace accidents and injuries. This ensures the safety of the work environment and addresses concerns related to the well-being of human workers.

Upskilling the Workforce:

While robots handle routine and repetitive tasks, human workers can be upskilled to take on more complex and creative roles. This transformation allows employees to focus on tasks that require critical thinking, problem-solving, and innovation, creating a more dynamic and skilled workforce.

By embracing automation, manufacturers can overcome the challenges posed by the mass retirement of Baby Boomers and create more efficient, productive, and safer work environments. As technology continues to advance, the integration of robotics into manufacturing processes stands as a promising strategy to ensure the industry’s sustained growth in the face of an evolving labor landscape.