EPIC’s Chris Walker, won Midwest Optical Systems first ever photo contest. Walker submitted photos of an application where he used several types of polarizing filters to inspect a black bead of material for width, position, and consistency within a cylindrical object.

Technical spec’s:

Application: Inspection of a black bead of material for size, position and consistency

Camera: Multiple Cognex cameras

Area of Spectrum: Visible

Light Source: Xenon Strobe light source with Fiber Optic cable to end-effector

Filters Used: PS007 Custom shaped Linear Polarizer, BP550 IR Block – Visible Bandpass Filter, AC380 Protective Acrylic Window

Application:

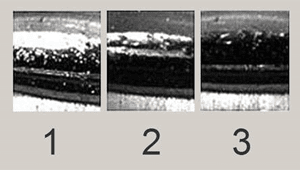

(Image 1) With no filter applied to the vision system, glare was present on the black material. This level of glare caused the system to be unable to recognize the inconsistencies in the bead.

(Image 2) To help reduce glare a custom shaped polarizing filter was applied. The geometry of the filters served to polarize the light source in such a way that would benefit every camera inspecting the product.

(Image 3) Glare is then eliminated completely by using a BP550 filter to eliminate any UV or IR generated from the Xenon light source. This filter was necessary because standard filters do not polarize light in this range of the spectrum.

EPIC Systems vision engineers understand that no two vision applications are identical. For that reason, each application is tailored to meet the customer’s needs. Contact EPIC Systems to see how our vision engineers “Do it Better”.