How much automation is right for your packaging line? Which processes can you automate for the highest ROI? When is the right time to automate? These can be hard questions to navigate, but an experienced packaging integrator can help you figure out the answers.

Five Factors to Consider When Determining Automated Packaging

1. What level of production do you need?

One of the biggest reasons to automate packaging is to speed up the process and produce more packaged product in a day. Consider if the demand for you product really requires an automated packaging line solution. A manual packaging process can be appropriate for small operations or low-volume applications.

2. Which parts of the packaging line will automation have the highest impact on?

Which part of your packaging process is the most time consuming? Filling? Case erecting? Look to automate the areas that have the biggest impact on speed first – scale-up automation based on a balance between gains in speed and cost (which brings us to factor #3)

3. Which parts of the packaging process cost the most to automate?

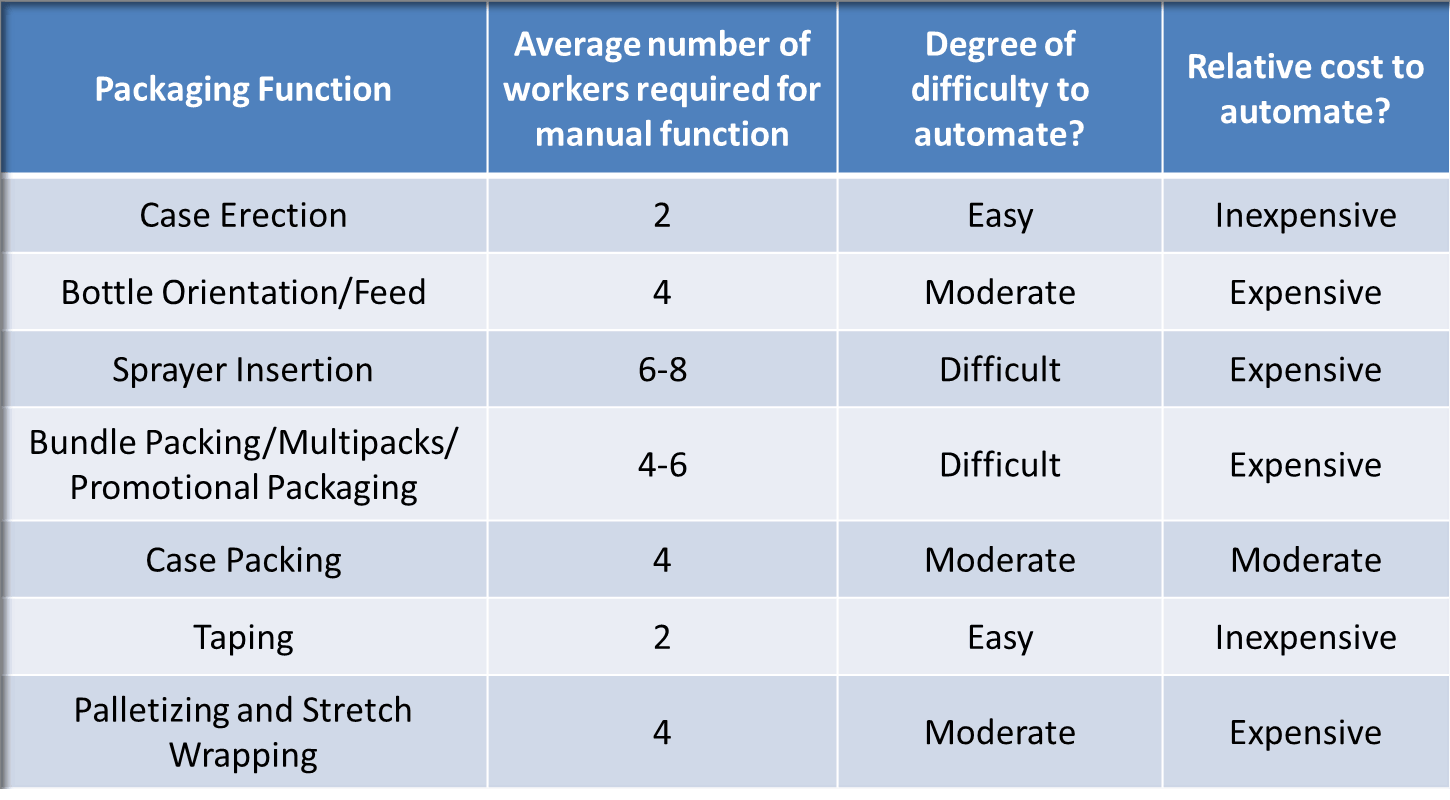

The most expensive pieces of packaging equipment might not have the biggest impact. For example, automating a sprayer inserter is both difficult and expensive, and it doesn’t have the same impact on your line speed as automating case erection or case packing – both of which are much less expensive to implement.

4. How flexible does your line need to be?

If you are trying to run multiple products, packaging sizes, and run lengths on a single line, a semi-automated solution may actually be better than a fully automated solution. A for the filling & product conveying, combined with hand-packing provides the flexibility for these various packages and runs at reasonable cost.

5. How complex is your packaging operation?

Contrary to popular belief, automation can actually be less accurate than manual operations for complex packaging applications. Automating certain complex processes can result in more packaging waste and un-reliable results. Consult with a packaging automation expert to determine if your process might be difficult to automate.

Packaging automation requires a delicate balance of many factors including cost, efficiency gain, and long-term benefit. Here is an example of how a few of these factors compare for some common pieces of packaging equipment:

Looking for more information? Contact a packaging engineer or learn more about what EPIC Packaging Systems has to offer…