There are more and more people offering machine vision system integration services

1. RELATIONSHIPS WITH CLIENTS

A good machine vision integrator will treat the machine vision project as a collaboration between client and integrator. Ask for past references on machine vision jobs and contact them. References and the client should substantiate the integrator values its relationship with clients by doing the following things:

-

- Thoroughly explaining all steps at the beginning and throughout the machine vision integration job

- Providing a comprehensive quote that outlines all elements of the job before the contract is signed

- Detailed development and installation schedules are provided

- Any changes in schedule, cost or scope are discussed as they arise and client decisions are respected

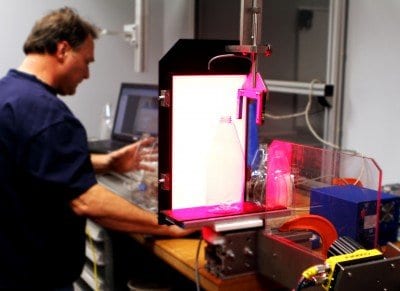

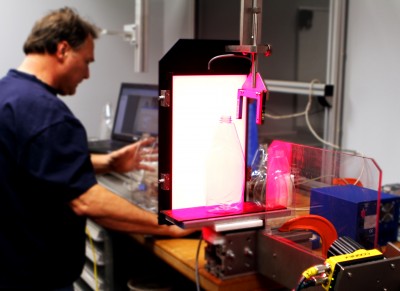

2. FEASIBILITY LAB

Every good machine vision integrator will have a feasibility lab. The purpose of a feasibility lab is to thoroughly develop the scope and specifications of a machine vision job by creating a miniature version of the proposed system and testing its capabilities. Feasibility studies are used to determine the optimum:

-

- Lighting strategy

- Lens selection

- Camera selection

- Equipment arrangement

Feasibility studies normally involve:

-

- Developing a thorough understanding of the client’s vision need

- Gaining knowledge of unique part and process variations

- Identifying the precise defects that need to be detected

- Acquiring sample products or parts that are to be inspected

- Mocking up complete vision configuration using cameras, lighting, and lenses

- Obtaining measurements to create a mechanical and electrical design to meet the requirements of the inspection system and plant facility

- Delivery of feasible pass/fail rate results and detailed system recommendations

3. FRONT-END ENGINEERING

As part of the vision feasibility study, front-end engineering should be completed. This may be called something different depending on the company, but the basic concept is the same. The goal is to fully understand exactly what it is you’re trying to achieve with vision inspection technology including any custom specifications and pass/fail rate success criteria. Front-end engineering determines the following things:

-

- Criteria for success and what success means exactly

- Motivational drive for the new process system

- Must-have features and want-to-have features

- Overall goals and objectives for the application

- Plant standards, manufacturing procedures and preferences

The use of a thorough Front-End Engineering program guarantees the following things:

-

- Comprehensive process system quotation, including a fixed-bid price and detailed project execution strategy

- The final system delivered is exactly what you need to meet your process goals

- Systems are designed to anticipate changing needs, alterations or special configurations

- System scope stays within budget and remains on schedule

4. PROJECT MANAGEMENT AND TECHNICAL EXPERTISE

Whether the integrator you are considering only does machine vision systems or they are a multi-discipline engineering firm, proven project management skills are key to the success of your project. Again, ask for references and follow through with them. Also, make sure the company can provide examples of past successful projects and speak in detail about the challenges and progressive steps of your advanced machine vision system project. Experienced project managers can make a huge difference in the outcome, speed, and cost of your project.

Providing examples of past projects and being able to discuss your potential project in detail also demonstrates technical expertise. Be wary of companies that claim your machine vision project will be easy. No machine vision application is easy; each is unique because your product is undoubtedly different from the last product the technology was applied to. A good machine vision integrator will understand this, and they will be honest about the technical challenges of the situation. Line rates, product shape, size or color, detection parameters; these are all factors that vary by client and have major effects on the configuration of a potential vision system.

5. OPEN DOOR POLICY

Not only should you ask for references, but you should also visit your vision integrator at their site. See what they do on a daily basis. Ask to tour their feasibility lab and explain the basics of what is done in the lab. Speak to the vision engineers who will be working on your project. This is the best way to truly get a feel for who your vision integrator is and whether or not they can provide the type of service and relationship you are looking for. Good vision integrators will be more than willing to show you around, and the best will invite you out to their facility without you even having to ask. This lets you know that the integrator values their relationship with you and is proud of the systems they produce.

EPIC Systems, Inc is a machine vision integrator located in St. Louis, MO. To learn more about EPIC, visit our website or contact an engineer today.